- plastechpollachi@gmail.com

- 9443262270

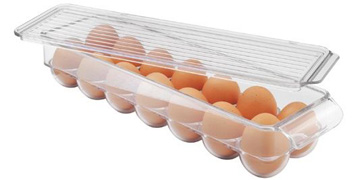

Multipurpose Pre Forms Transparent, Wear-Resisting and Corrosion-Resisting Plastics with High Strength and Smooth finish

Carbonated Soft Drinks

The material must be extremely strong to contain the internal pressures of CO2 without distortion or expansion.

Beer Bottles

Beer needs higher performance in both CO2 and O2 barriers compared to PET used in CSD applications.

Recycle PET

Post-consumer recycled PET (PCR PET) can be used for clothing and carpet fiber, and fiberfill for stuffing articles such as pillows.

Juice Bottles

Juices and many other products such as sport drinks or other high acid drinks are hot filled into PET bottles.

Our PET Preforms Plastech preform technology combines PET with the latest barrier and oxygen scavenging resins.

Video Tutorial Here's the best part of our impressive services.

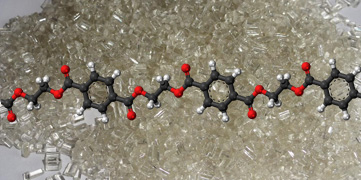

What is PET (PolyEthylene Terephthalate) ?

It's a plastic resin and the most common type of polyester. Two monomers modified ethylene glycol and purified terephthalic acid are combined to form the polymer called polyethylene terephthalate. PET was discovered and patented in England in 1941.

Read More

Why PET (PolyEthylene Terephthalate) ?

Because it's safe, strong, transparent and versatile. Customers choose it for its safety, light weight, resealability, shatter-resistance and recyclability. Up to 100% of a PET package can be made from recycled PET, and the material can be recycled again and again.

Read More

Why is PET a Sustainable Packaging Option?

First and foremost, a sustainable package must serve its essential function: to protect the product it contains, delivering it safely with all of its features and benefits intact. Beyond this, sustainable package manufacturers look to reduce the environmental footprint of their package

Read More

- Powered by Roftr.